How 3D Printing is Revolutionizing Product Development

3D printing has ushered in a new era of innovation across various industries, fundamentally transforming traditional product development processes. This article explores how 3D printing is revolutionizing product development, enhancing design flexibility, accelerating prototyping, and fostering creativity.

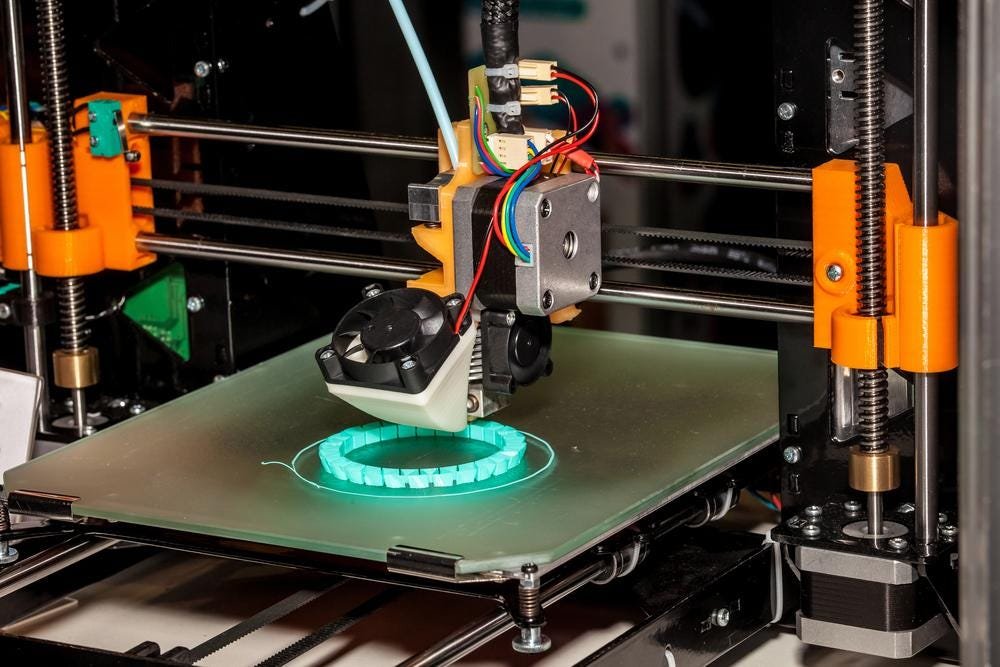

Introduction to 3D Printing in Product Development

3D printing has emerged as a disruptive technology, enabling manufacturers to create intricate designs and functional prototypes with unprecedented precision. This article examines its impact on accelerating innovation and reshaping product development strategies.

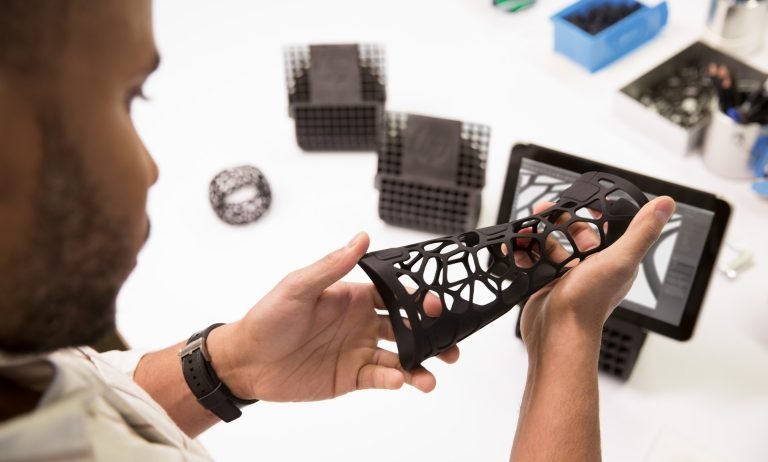

Enhancing Design Flexibility and Customization

One of the key benefits of 3D printing is its ability to enhance design flexibility and customization. Designers can iterate quickly on prototypes, experimenting with complex geometries and customized features that were once impractical with traditional manufacturing methods. This capability allows for rapid iteration and refinement based on real-world testing and user feedback.

Accelerating Prototyping and Time-to-Market

3D printing accelerates prototyping by reducing lead times and costs associated with tooling and production setup. Designers can produce functional prototypes rapidly, allowing for early-stage testing, validation of design concepts, and identification of potential improvements. This agility shortens product development cycles and enables faster time-to-market for new innovations.

Facilitating Complex and Lightweight Structures

Traditional manufacturing methods often impose limitations on the complexity and intricacy of product designs. 3D printing overcomes these constraints by enabling the production of complex geometries, lightweight structures, and integrated components in a single manufacturing process. This capability unlocks new possibilities in industries such as aerospace, automotive, and healthcare, where lightweight and durable materials are crucial.

Reducing Costs and Waste in Production

By eliminating the need for costly tooling and reducing material waste, additive manufacturing offers significant cost savings in product development and manufacturing. Manufacturers can optimize material usage, produce on-demand parts, and iterate designs without incurring additional expenses associated with traditional manufacturing processes. This efficiency makes 3D printing economically viable for small-batch production and customized products.

Innovating Sustainable Manufacturing Practices

Sustainability is a growing concern in product development and manufacturing. Additive manufacturing supports sustainable practices by minimizing material waste, energy consumption, and carbon footprint compared to conventional manufacturing methods. Additive manufacturing techniques, such as using recycled materials and biodegradable polymers, further contribute to environmentally friendly production processes.

Overcoming Challenges and Limitations

Despite its advantages, additive manufacturing faces challenges such as limited material choices, production speed for large volumes, and post-processing requirements. Manufacturers must address these limitations through ongoing research, technological advancements, and strategic integration of 3D printing within existing manufacturing workflows.

Embracing Future Innovations and Applications

The future of 3D printing in product development holds promise for advancements in materials science, printing technologies, and industrial applications. Innovations like multi-material printing, bio-printing for medical applications, and on-site manufacturing in remote locations are expanding the scope and potential of additive manufacturing technologies.

Conclusion

In conclusion, 3D printing is revolutionizing product development by offering unparalleled design flexibility, accelerating prototyping timelines, and promoting sustainable manufacturing practices. As technology continues to evolve, businesses across industries are leveraging additive manufacturing to drive innovation, reduce costs, and bring new products to market faster than ever before. By embracing additive manufacturing capabilities, organizations can stay ahead in a competitive market landscape and meet evolving consumer demands for customized, high-performance products.